Careers in Naval Architecture

1. Introduction

A Naval Architect is a professional engineer who is responsible for the design, construction and repair of ships, boats, other marine vessels and offshore structures, both civil and military, including:

Merchant ships - Oil/Gas Tankers, Cargo Ships, Cruise Liners, etc

Merchant ships - Oil/Gas Tankers, Cargo Ships, Cruise Liners, etc - Passenger/Vehicle Ferries

- Warships - Frigates, Destroyers, Aircraft Carriers, Amphibious Ships, etc

- Submarines and underwater vehicles

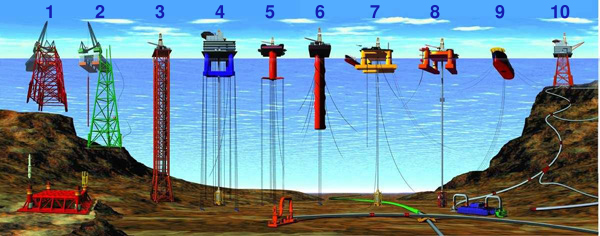

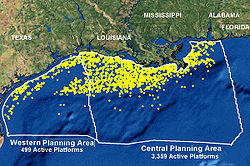

- Offshore Drilling Platforms, Semi Submersibles, FPSOs

- High Speed Craft - Hovercraft, Multi-Hull Ships, Hydrofoil Craft, etc

- Workboats - Fishing Vessels, Tugs, Pilot Vessels, Rescue Craft etc

- Yachts, Power Boats and other recreational craft

Some of these are among the largest and most complex and highly valued moveable structures produced by mankind. Without them to provide for the safe and efficient transport and recovery of the world's raw materials and products, modern society as we know it could not exist.

Modern engineering on this scale is essentially a team activity conducted by professional engineers in their respective fields and disciplines. However, it is the Naval Architect who integrates their activities and takes ultimate responsibility for the overall project. This demanding leadership role requires managerial qualities and ability to bring together the often conflicting demands of the various professional engineering disciplines involved to produce a product which is "fit for the purpose".

In addition to this vital managerial role, the Naval Architect has also a specialist function in ensuring that a safe, economic and seaworthy design is produced.

In addition to this vital managerial role, the Naval Architect has also a specialist function in ensuring that a safe, economic and seaworthy design is produced.

To undertake all these tasks the Naval Architect must have an understanding of many branches of engineering and must be in the forefront of high technology areas such as computer aided design and calculation. He or she must be able to utilise effectively the services provided by scientists, lawyers, accountants and business people of many kinds.

A Naval Architect requires a creative, enquiring and logical mind; the ability to communicate clearly in speech and writing with others inside and outside the engineering profession; sound judgment and qualities of leadership. The education and training given to the Naval Architect are designed to develop these skills and to lead him or her to recognised qualifications and professional status.

2. A Variety of Careers

Naval Architects have a wide range of employment opportunities, both in the UK and world-wide. They are involved in such a wide variety of work that it is difficult to categorise it comprehensively. However, the main areas are as follows:

Design

Design - Construction and Repair

- Consultancy

- Marketing and Sales

- Operations

- Regulation, Surveying and Overseeing

- Research and Development

- Education and Training

Each type of work has its own distinctive character and offers opportunities for initiative and imagination in a wide variety of technical and managerial posts as well as opportunities for foreign travel. The work place may be a large company, a small group, a consultancy or a government department.

Depending mainly on the type of qualifications held and personal inclination, Naval Architects may become specialists in one field or develop broad experience in several. Eventually they may find themselves in senior executive positions using their knowledge and experience of general management as well as their professional skills in engineering and project leadership. Indeed, aided by the breadth of their education, training and experience, professional Naval Architects are successful in top management posts in government, industry and commerce quite outside the maritime field.

Design

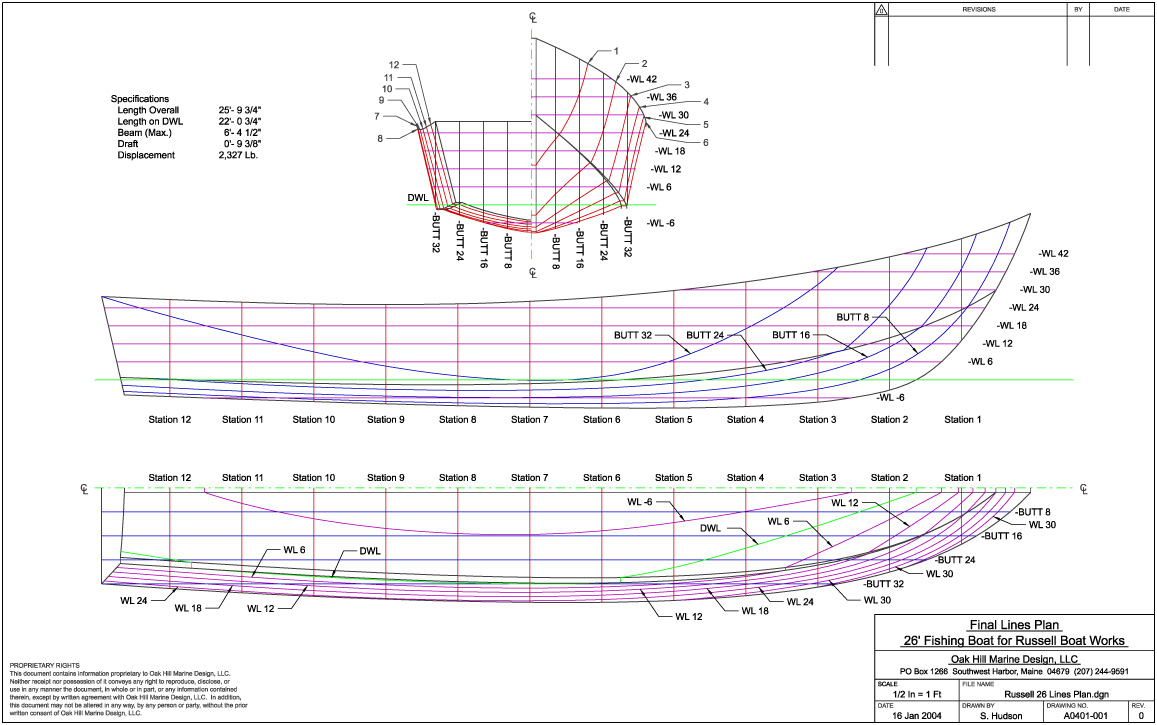

Naval Architects are by necessity creative people. They must have an understanding of the many facets of ship design - function, appearance and especially important at sea, safety. They must be team leaders, able to integrate the inputs of many others to achieve a balanced and coherent whole. Apart from the architectural aspects of ship form and layout, they must be able to use complex mathematical and physical models to ensure that the design is satisfactory technically and that it meets the safety rules and standards laid down by Classification Societies and Government Agencies.

Naval Architects are by necessity creative people. They must have an understanding of the many facets of ship design - function, appearance and especially important at sea, safety. They must be team leaders, able to integrate the inputs of many others to achieve a balanced and coherent whole. Apart from the architectural aspects of ship form and layout, they must be able to use complex mathematical and physical models to ensure that the design is satisfactory technically and that it meets the safety rules and standards laid down by Classification Societies and Government Agencies.

A ship, boat or offshore structure must be stable, seaworthy and have adequate strength in all weathers as well as the hydrodynamic (and, for sailing craft, aerodynamic) performance to give economic propulsion and safe and comfortable motion in all sea states. The design process demands the extensive employment of computer based information and communication systems.

Employers of Naval Architects involved in design work include ship and boat builders, offshore constructors, design consultants, and for the ships and submarines of the Royal Navy, the Ministry of Defence. Major equipment manufacturers also employ teams of engineers, including Naval Architects, on the design of such products as propulsion systems, auxiliary systems, subsea production systems and control systems.

Construction and Repair

The task of the ship and boat builder and offshore constructor is to convert drawings and detailed specifications into real structures. A Naval Architect specialising in construction usually holds a management post, taking responsibility for the management of the whole yard or for sections of it such as planning, production or the complex operation of fitting out. There is a continuous striving to make savings with existing techniques and equipment through the adoption of new processes and practices and by better training for the work force. The Naval Architect must also organise the supply of materials and components, inspection and testing as well as the vital resources of manpower.

The task of the ship and boat builder and offshore constructor is to convert drawings and detailed specifications into real structures. A Naval Architect specialising in construction usually holds a management post, taking responsibility for the management of the whole yard or for sections of it such as planning, production or the complex operation of fitting out. There is a continuous striving to make savings with existing techniques and equipment through the adoption of new processes and practices and by better training for the work force. The Naval Architect must also organise the supply of materials and components, inspection and testing as well as the vital resources of manpower.

Repair work has much in common with construction. Naval Architects in this field become professional managers who, like the builders, need to master modern management and associated techniques. Emergency repair work often offers opportunities for ingenuity and on-the-spot improvisation, and in the offshore engineering world in particular repair frequently involves underwater technology.

Employers of Naval Architects in construction and repair include both large and small shipbuilders and repairers, and those involved in the maintenance and repair of naval ships and submarines. A large proportion of senior technical managers and executives in the UK maritime industry are those who have been educated and trained as Naval Architects.

Consultancy

As consultants, Naval Architects provide clients with engineering solutions, technical and commercial guidance, support and project management for concept design studies, new vessel constructions, refits and conversions. The variety of work provides a rewarding challenge to the Naval Architect.

Marketing and Sales

Naval Architects are employed to give professional advice and technical support to customers of the maritime industry.

Operations

Many shipping companies have technical departments in which Naval Architects are responsible for the many phases of ship and equipment procurement and for solving problems affecting the economics of maritime operations.

Regulation, Surveying and Overseeing

Naval Architects employed by Classification Societies as Ship Surveyors are engaged world-wide in evaluating the safety of ships and marine structures using the Society's Rules and those of intergovernmental organisations such as the International Maritime Organisation. Plans of ships to be built and eventually classed with the Society are scrutinised, and aspects of design such as strength, stability, and lifesaving approved before construction.

During construction, Ship Surveyors carry out inspections to ensure that the quality of the workmanship and materials used is in accordance with the Rules and Regulations. Once the vessel or structure is in service, Ship Surveyors will continue to carry out inspections to ensure that any serious defects arising from operation are made good and that a safe and seaworthy structure is maintained. Government Departments employ Naval Architects who deal mainly with the framing of safety regulations and the surveying of ships and equipment from the safety point of view.

Ship operators and the Ministry of Defence employ Naval Architects to oversee the construction and repair of their vessels.

Research and Development

Research and Development

Maritime research in the UK enjoys a high reputation world-wide and Naval Architects, many with post-graduate qualifications, are engaged in research in universities and industry throughout the country. Classification Societies also devote resources to Research and Development employing Naval Architects in this field.

Education and Training

Careers in engineering demand a sound education. Consequently, there is a need to attract Naval Architects with above average qualifications into Universities and Colleges as professors and lecturers.

3. How to Become a Naval Architect

A fully qualified Naval Architect is a member of The Royal Institution of Naval Architects (RINA) who is registered with the UK Engineering Council (EC) as a Chartered Engineer (CEng), Incorporated Engineer (IEng) or Engineering Technician (EngTech).

Chartered Engineers are primarily concerned with innovation, creativity and change, the development and use of new technologies, the promotion and use of advanced design and production methods, and the pioneering of new engineering services and management techniques in the field of naval architecture and maritime technology.

Chartered Engineers are primarily concerned with innovation, creativity and change, the development and use of new technologies, the promotion and use of advanced design and production methods, and the pioneering of new engineering services and management techniques in the field of naval architecture and maritime technology.

- Incorporated Engineers are primarily concerned with the efficient management of existing technology at peak efficiency in the fields of naval architecture and maritime technology, and have managerial responsibility as leaders of teams, or individual responsibility at a high level.

- Engineering Technicians are primarily concerned with the application of proven techniques to the solution of practical problems in the fields of naval architecture and maritime technology.

The RINA exercises strict controls over engineering professional standards for Naval Architects, and for membership it is necessary

- to have an accredited academic qualification such as a degree or diploma, or to have passed examinations of an equivalent standard

- to have received at least two years of training or a sufficient period of experience in lieu of training

- to have held a relevant responsible position for at least two years

- to have an aggregate of seven years of education, training and responsible experience after reaching the age of 18 years

The CEng, IEng and EngTech titles can only be obtained through membership of a professional engineering institution such as the RINA. There are classes of membership of the RINA which correspond to these titles. Members of the RINA are qualified to register as CEng, Associate Members as IEng and Associates as EngTech. Students who are studying to achieve the academic qualification required to become a Member, Associate Member or Associate may join the RINA as a Student Member. Those who have gained the academic qualification may then transfer to Graduate Member.

Such is the complexity of most engineering products that many people need to contribute as a team to the manufacturing process, whether as Chartered Engineers, Incorporated Engineers or Engineering Technicians, bringing together their different skills. This booklet is mainly intended for prospective Chartered Engineers and Incorporated Engineers, who require a degree as the educational qualification. However, the RINA can offer advice to those who are more interested in the practical aspects of naval architecture and who wish to become Engineering Technicians.

Education

Education

The accreditation of a course by the RINA or another engineering professional institution ensures that its qualities are such that those who satisfy its requirements meet the educational standards of membership and registration. All accredited courses must contain certain features and essential components, but individual courses will differ in structure and content. The prospectuses of universities and colleges should be consulted in the initial selection of a course.

While the majority of Student Members will follow educational courses accredited by the RINA, students of other engineering disciplines who intend to work in the maritime industries are also eligible for membership. They should ensure that their studies will lead to an educational qualification which entitles them to become members of the RINA and register with the EC.

At school or college a broad range of subjects should be studied at GCSE level, covering both the arts and sciences, including the essential subjects Mathematics, Physics and English. These studies should lead to qualifications satisfying the entry requirements for either an accredited masters degree (MEng) course if proposing to become a Chartered Engineer, or a degree (BEng) course if intending to become an Incorporated Engineer. However, honours degree BEng graduates may also qualify for registration as a Chartered Engineer after completing additional academic studies, which may be achieved by a formal course at university or college, by distance learning such as through the Open University, by work based learning assessed during employment, or by a combination of these. Similarly, a diploma graduate may follow a similar route to qualify for registration as an Incorporated Engineer.

Applicants for entry to degree courses are normally expected to offer three GCE 'A' levels, or five Scottish 'Highers', with good grades in Mathematics and Physics. Acceptance on a particular course may be dependent on an interview as well as the grades achieved.

Bridges between educational routes exist, and students with suitable diploma qualifications may enter or transfer to BEng courses. Similarly, students may transfer from BEng to MEng courses.

Bridges between educational routes exist, and students with suitable diploma qualifications may enter or transfer to BEng courses. Similarly, students may transfer from BEng to MEng courses.

All degree courses accredited by the RINA involve the study of engineering, materials, design theories and methods, mathematics and numerical methods, management, manufacturing systems and methods as well as naval architecture. At least 50% of each course marine orientated and contains a major project and engineering applications.

For those who are unable to attend a degree course, the RINA's educational requirements will be satisfied by passing the EC's examinations or an approved study profile for an Open University degree.

Candidates for membership of the RINA offering degrees accredited by other professional engineering institutions may be required to gain additional training/experience to compensate for any deficiencies in the above studies. Specialisation is a normal feature of a degree course and the options available may have a considerable influence on the choice of course.

A number of organisations including the RINA offer scholarships which provide additional financial support during an educational course.

Training

Although a number of companies have training schemes accredited by the RINA, the majority of trainees will need to work to individual programmes also approved by the RINA. In the latter case, the RINA can assist trainees in developing their individual training programmes.

When the company or individual training programme has been agreed, a senior engineer will be appointed to act as a mentor.

The Institution's training requirements call for a structured, broad and integrated programme, which should encompass the full range of practices applicable to the maritime industry. There are three parts to the Naval Architect's training:

Design

Design

The trainee Naval Architect is required to gain an insight into the design process as well as communication and information systems by being involved in typical design issues such as requirements, functions, analyses, materials, production processes, quality, reliability, appearance and costs, hazard identification and risk assessment techniques.

Engineering Practice

Projects and departmental attachments are used to cover important applications to engineering and technology involving the wide range of materials and components employed in the marine industry, processes such as material forming, removal, joining and fabrication and their control, and assembly, installation and commissioning.

Management Services

The object of this part of training is to give the Naval Architect an awareness of important management practices such as production planning and control, quality control and assurance, interpersonal skills and personnel management, and commercial, marketing, legal and financial implications.

Some companies may not be able to provide all of the above required training themselves and may wish to attach their trainees to other organisations for certain parts of the planned training. Such attachments may also be used to cover vital elements more efficiently or to provide a broader appreciation of the wide range of expertise required by the Naval Architect.

When writing to potential sponsors or employers or responding to offers of training or sponsorship, it is important to enquire whether the company scheme meets, or the company is prepared to assist in meeting, the requirements of the RINA.

Experience

After the completion of education and training there follows a period in which the prospective Naval Architects gain responsible experience in posts which require them to develop and prove fully their technical competence, and to demonstrate a satisfactory range of functions and characteristics such as the exercise of independent technical judgement requiring both practical experience and the application of engineering principles.

After the completion of education and training there follows a period in which the prospective Naval Architects gain responsible experience in posts which require them to develop and prove fully their technical competence, and to demonstrate a satisfactory range of functions and characteristics such as the exercise of independent technical judgement requiring both practical experience and the application of engineering principles.

A minimum of two years of responsible experience is required and on completion an application should be made to the RINA for transfer to the class of Member or Associate Member, which authorises the use of the letters MRINA or AMRINA after a member's name. Successful candidates for transfer to Member or Associate Member will be offered registration with the EC which authorises them to also use the style or title of Chartered Engineer or Incorporated Engineer and the designatory letters CEng or IEng. Application may also be made by Chartered Engineers to the RINA to use the title of European Engineer (Eur Ing).

Professional Development

As a Chartered Engineer or Incorporated Engineer gains experience, the choice of career widens and after a few years opportunities may occur in many of the areas mentioned earlier. Later a Naval Architect may move from technical to general management to secure senior positions and ultimately directorships. While often regarded as being strictly vocational, engineering can also be an ideal base for a wide variety of careers outside the maritime industry.

Naval Architects must be prepared to keep abreast of developments in modern technology, to adapt to rapidly changing circumstances and to take advantage of new career opportunities as they arise. Continuing professional development (CPD) is therefore essential and can be achieved through courses and conferences which are organised by the RINA and other engineering professional institutions or organisations on new technologies, management systems, communication, business and many other topics. Naval Architects may also keep up-to-date by reading technical journals and papers published by professional institutions.

4. The Royal Institution of Naval Architects

Founded in 1860, The Royal Institution of Naval Architects is an internationally renowned professional engineering institution whose members are involved at all levels in the design, construction, repair and operation of ships, boats and marine structures. Members of the RINA are widely represented in industry, universities and colleges, and maritime organisations worldwide. There are classes of membership to suit all those who are professionally qualified in naval architecture, or who are involved or interested in the maritime industry.

Founded in 1860, The Royal Institution of Naval Architects is an internationally renowned professional engineering institution whose members are involved at all levels in the design, construction, repair and operation of ships, boats and marine structures. Members of the RINA are widely represented in industry, universities and colleges, and maritime organisations worldwide. There are classes of membership to suit all those who are professionally qualified in naval architecture, or who are involved or interested in the maritime industry.

The RINA enjoys an outstanding reputation for the quality and range of its technical publications, covering all aspects of naval architecture and the maritime industry. The RINA also organises an extensive and successful programme of international conferences and training courses covering a broad range of experience and opinion on research, development and operation of all aspects of naval architecture.

Membership of the RINA gives the following benefits and services:

- A professional qualification which is internationally recognised as demonstrating the achievement of the highest standards of professional competence

- Free copies of the leading technical journals, The Naval Architect, Offshore Marine Technology and Warship Technology, and reduced rates on all other RINA publications

- Reduced rates for all RINA international conferences and training courses

- Advice and assistance on all aspects of academic study, training and professional development

- Access to library and technical research facilities

- Opportunity to meet and exchange views with other professionals in the maritime industry, at local Branch meetings and conferences

Students at schools and colleges who are studying to enter university and are interested in a career as a Naval Architect may also join the RINA as a Student Companion member. Further information can be obtained from the Professional Affairs Department.

5. Information

The Professional Affairs Department of the Royal Institution of Naval Architects can advise on suitable courses in naval architecture and related subjects. The Professional Affairs Departmentcan also advise students on any other engineering courses who may subsequently wish to consider a career in naval architecture

Merchant ships - Oil/Gas Tankers, Cargo Ships, Cruise Liners, etc

Merchant ships - Oil/Gas Tankers, Cargo Ships, Cruise Liners, etc  In addition to this vital managerial role, the Naval Architect has also a specialist function in ensuring that a safe, economic and seaworthy design is produced.

In addition to this vital managerial role, the Naval Architect has also a specialist function in ensuring that a safe, economic and seaworthy design is produced. Design

Design  Naval Architects are by necessity creative people. They must have an understanding of the many facets of ship design - function, appearance and especially important at sea, safety. They must be team leaders, able to integrate the inputs of many others to achieve a balanced and coherent whole. Apart from the architectural aspects of ship form and layout, they must be able to use complex mathematical and physical models to ensure that the design is satisfactory technically and that it meets the safety rules and standards laid down by Classification Societies and Government Agencies.

Naval Architects are by necessity creative people. They must have an understanding of the many facets of ship design - function, appearance and especially important at sea, safety. They must be team leaders, able to integrate the inputs of many others to achieve a balanced and coherent whole. Apart from the architectural aspects of ship form and layout, they must be able to use complex mathematical and physical models to ensure that the design is satisfactory technically and that it meets the safety rules and standards laid down by Classification Societies and Government Agencies. The task of the ship and boat builder and offshore constructor is to convert drawings and detailed specifications into real structures. A Naval Architect specialising in construction usually holds a management post, taking responsibility for the management of the whole yard or for sections of it such as planning, production or the complex operation of fitting out. There is a continuous striving to make savings with existing techniques and equipment through the adoption of new processes and practices and by better training for the work force. The Naval Architect must also organise the supply of materials and components, inspection and testing as well as the vital resources of manpower.

The task of the ship and boat builder and offshore constructor is to convert drawings and detailed specifications into real structures. A Naval Architect specialising in construction usually holds a management post, taking responsibility for the management of the whole yard or for sections of it such as planning, production or the complex operation of fitting out. There is a continuous striving to make savings with existing techniques and equipment through the adoption of new processes and practices and by better training for the work force. The Naval Architect must also organise the supply of materials and components, inspection and testing as well as the vital resources of manpower. Research and Development

Research and Development Chartered Engineers are primarily concerned with innovation, creativity and change, the development and use of new technologies, the promotion and use of advanced design and production methods, and the pioneering of new engineering services and management techniques in the field of naval architecture and maritime technology.

Chartered Engineers are primarily concerned with innovation, creativity and change, the development and use of new technologies, the promotion and use of advanced design and production methods, and the pioneering of new engineering services and management techniques in the field of naval architecture and maritime technology. Education

Education Bridges between educational routes exist, and students with suitable diploma qualifications may enter or transfer to BEng courses. Similarly, students may transfer from BEng to MEng courses.

Bridges between educational routes exist, and students with suitable diploma qualifications may enter or transfer to BEng courses. Similarly, students may transfer from BEng to MEng courses. Design

Design  After the completion of education and training there follows a period in which the prospective Naval Architects gain responsible experience in posts which require them to develop and prove fully their technical competence, and to demonstrate a satisfactory range of functions and characteristics such as the exercise of independent technical judgement requiring both practical experience and the application of engineering principles.

After the completion of education and training there follows a period in which the prospective Naval Architects gain responsible experience in posts which require them to develop and prove fully their technical competence, and to demonstrate a satisfactory range of functions and characteristics such as the exercise of independent technical judgement requiring both practical experience and the application of engineering principles. Founded in 1860, The Royal Institution of Naval Architects is an internationally renowned professional engineering institution whose members are involved at all levels in the design, construction, repair and operation of ships, boats and marine structures. Members of the RINA are widely represented in industry, universities and colleges, and maritime organisations worldwide. There are classes of membership to suit all those who are professionally qualified in naval architecture, or who are involved or interested in the maritime industry.

Founded in 1860, The Royal Institution of Naval Architects is an internationally renowned professional engineering institution whose members are involved at all levels in the design, construction, repair and operation of ships, boats and marine structures. Members of the RINA are widely represented in industry, universities and colleges, and maritime organisations worldwide. There are classes of membership to suit all those who are professionally qualified in naval architecture, or who are involved or interested in the maritime industry.